DIN338 fullkomlega slípuð HSS M2 snúningsbor

Eiginleikar

DIN338 fullslípaða HSS M2 snúningsborið hefur nokkra framúrskarandi eiginleika, þar á meðal:

Hraðstál (HSS) M2 efni: Notkun HSS M2 efnis veitir framúrskarandi hörku, slitþol og hitaþol, sem gerir þessar borbitar hentuga til að bora í fjölbreytt efni, þar á meðal ryðfrítt stál, álfelgað stál og ómálmkennt efni.

FULLSLÍPAÐAR FLÖTUR OG SKURBRÝNIR: Borkrónan er nákvæmnisslípuð til að veita skarpar og samræmdar raufar og skurðbrúnir, sem leiðir til bættrar flísafrásogs, minni núnings og aukinnar nákvæmni í borun.

135 gráðu klofningspunktur: Borinn er með 135 gráðu klofningspunktshönnun sem dregur úr þörfinni fyrir forholur, eykur miðjunga og sjálfmiðjunargetu og bætir skilvirkni borunar.

GLJÁANDI ÁFERÐ: Björt áferð borsins stendst tæringu, stuðlar að flæði flísar og veitir betri sýnileika meðan á notkun stendur, sem hjálpar til við að bæta afköst og endingartíma.

DIN338-samræmi: Borvélar eru í samræmi við DIN338 staðla, sem tryggir samræmdar stærðir, hágæða framleiðslu og uppfyllir iðnaðarstaðla um nákvæmni og áreiðanleika.

Fjölhæf notkun: Þessir snúningsborar henta fyrir almenn borunarverkefni í fjölbreyttum efnum, sem gerir þá fjölhæfa og hagnýta fyrir fjölbreytt borunarforrit.

Langur endingartími verkfæra: Samsetning hágæða HSS M2 efna, nákvæmrar slípunar og endingargóðrar hönnunar hjálpar til við að lengja endingartíma verkfæra og draga úr tíðni skipta og viðhalds.

Saman gera þessir eiginleikar DIN338 fullslípuðu HSS M2 snúningsborinn að áreiðanlegu og afkastamiklu verkfæri fyrir faglegar og iðnaðarboranir.

VÖRUsýning

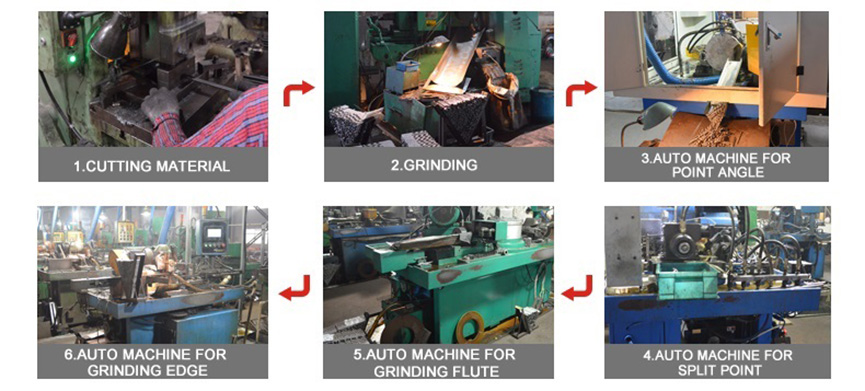

FERLIFLÆÐI

Kostir

DIN338 fullslípaðir HSS M2 snúningsborar bjóða upp á ýmsa kosti, þar á meðal:

Mikil endingu: HSS M2 efni býður upp á framúrskarandi hörku og slitþol fyrir langvarandi endingu, sérstaklega þegar borað er í gegnum erfið efni eins og ryðfrítt stál, álfelgur og málma sem ekki eru járn.

Nákvæmni og nákvæmni: Fullslípuð rif og skurðbrúnir tryggja nákvæma og samræmda borun og framleiða hrein og nákvæm göt.

Skilvirk flísafgangur: Nákvæmlega slípuð gróp og skurðbrúnir auðvelda skilvirka flísafgang, lágmarka stíflur og auka skilvirkni borunar.

Aukinn borhraði: 135 gráðu klofinn hönnun lágmarkar þörfina fyrir forborun, sem gerir kleift að bora hraðar og auka framleiðni.

MINNKAR HITA OG NÚNING: Háhraðastálsefni og nákvæm slípun hjálpa til við að draga úr hitauppsöfnun og núningi við borun, sem leiðir til mýkri notkunar og lengri endingartíma verkfærisins.

Tæringarþol: Bjarta yfirborðið á borbitanum er tæringarþolið, sem lengir líftíma borbitans og viðheldur skurðargetu hans. Fjölhæfni: Þessir borbitar henta fyrir fjölbreytt borunarforrit, sem gerir þá fjölhæfa og hagnýta til notkunar í ýmsum efnum og atvinnugreinum.

Með því að bjóða upp á þessa kosti býður DIN338 fullslípaði HSS M2 snúningsborinn upp á áreiðanleika, skilvirkni og endingu í borunaraðgerðum.

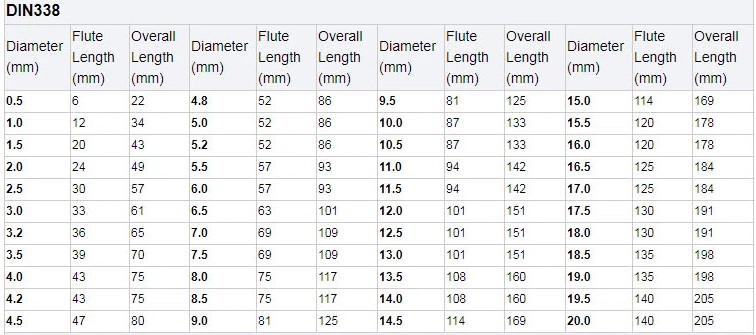

| DIN338 HSS snúningsborar | ||||||||

| Þvermál (mm) | Flautulengd (mm) | Heildarlengd (mm) | Þvermál (mm) | Flautulengd (mm) | Heildarlengd (mm) | Þvermál (mm) | Flautulengd (mm) | Heildarlengd (mm) |

| 0,2 | 2,5 | 19.0 | 5.6 | 57,0 | 93,0 | 11.0 | 94,0 | 142,0 |

| 0,3 | 3.0 | 19.0 | 5.7 | 57,0 | 93,0 | 11.1 | 94,0 | 142,0 |

| 0,4 | 5.0 | 20,0 | 5.8 | 57,0 | 93,0 | 11.2 | 94,0 | 142,0 |

| 0,5 | 6.0 | 22,0 | 5.9 | 57,0 | 93,0 | 11.3 | 94,0 | 142,0 |

| 0,6 | 7.0 | 24.0 | 6.0 | 57,0 | 93,0 | 11.4 | 94,0 | 142,0 |

| 0,7 | 9.0 | 28,0 | 6.1 | 63,0 | 101.0 | 11,5 | 94,0 | 142,0 |

| 0,8 | 10.0 | 30,0 | 6.2 | 63,0 | 101.0 | 11.6 | 94,0 | 142,0 |

| 0,9 | 11.0 | 32,0 | 6.3 | 63,0 | 101.0 | 11.7 | 94,0 | 142,0 |

| 1.0 | 12.0 | 34,0 | 6.4 | 63,0 | 101.0 | 11.8 | 94,0 | 142,0 |

| 1.1 | 14.0 | 36,0 | 6,5 | 63,0 | 101.0 | 11.9 | 101.0 | 151,0 |

| 1.2 | 16.0 | 38,0 | 6.6 | 63,0 | 101.0 | 12.0 | 101.0 | 151,0 |

| 1.3 | 16.0 | 38,0 | 6.7 | 63,0 | 101.0 | 12.1 | 101.0 | 151,0 |

| 1.4 | 18,0 | 40,0 | 6,8 | 69,0 | 109,0 | 12.2 | 101.0 | 151,0 |

| 1,5 | 18,0 | 40,0 | 6,9 | 69,0 | 109,0 | 12.3 | 101.0 | 151,0 |

| 1.6 | 20,0 | 43,0 | 7.0 | 69,0 | 109,0 | 12.4 | 101.0 | 151,0 |

| 1.7 | 20,0 | 43,0 | 7.1 | 69,0 | 109,0 | 12,5 | 101.0 | 151,0 |

| 1.8 | 22,0 | 46,0 | 7.2 | 69,0 | 109,0 | 12.6 | 101.0 | 151,0 |

| 1.9 | 22,0 | 46,0 | 7.3 | 69,0 | 109,0 | 12,7 | 101.0 | 151,0 |

| 2.0 | 24.0 | 49,0 | 7.4 | 69,0 | 109,0 | 12,8 | 101.0 | 151,0 |

| 2.1 | 24.0 | 49,0 | 7,5 | 69,0 | 109,0 | 12,9 | 101.0 | 151,0 |

| 2.2 | 27,0 | 53,0 | 7.6 | 75,0 | 117,0 | 13.0 | 101.0 | 151,0 |

| 2.3 | 27,0 | 53,0 | 7,7 | 75,0 | 117,0 | 13.1 | 101.0 | 151,0 |

| 2.4 | 30,0 | 57,0 | 7,8 | 75,0 | 117,0 | 13.2 | 101.0 | 151,0 |

| 2,5 | 30,0 | 57,0 | 7,9 | 75,0 | 117,0 | 13.3 | 108,0 | 160,0 |

| 2.6 | 30,0 | 57,0 | 8.0 | 75,0 | 117,0 | 13.4 | 108,0 | 160,0 |

| 2.7 | 33,0 | 61,0 | 8.1 | 75,0 | 117,0 | 13,5 | 108,0 | 160,0 |

| 2,8 | 33,0 | 61,0 | 8.2 | 75,0 | 117,0 | 13.6 | 108,0 | 160,0 |

| 2.9 | 33,0 | 61,0 | 8.3 | 75,0 | 117,0 | 13,7 | 108,0 | 160,0 |

| 3.0 | 33,0 | 61,0 | 8.4 | 75,0 | 117,0 | 13,8 | 108,0 | 160,0 |

| 3.1 | 36,0 | 65,0 | 8,5 | 75,0 | 117,0 | 13,9 | 108,0 | 160,0 |

| 3.2 | 36,0 | 65,0 | 8.6 | 81,0 | 125,0 | 14.0 | 108,0 | 160,0 |

| 3.3 | 36,0 | 65,0 | 8,7 | 81,0 | 125,0 | 14.3 | 114,0 | 169,0 |

| 3.4 | 39,0 | 70,0 | 8,8 | 81,0 | 125,0 | 14,5 | 114,0 | 169,0 |

| 3,5 | 39,0 | 70,0 | 8,9 | 81,0 | 125,0 | 14,8 | 114,0 | 169,0 |

| 3.6 | 39,0 | 70,0 | 9.0 | 81,0 | 125,0 | 15,0 | 114,0 | 169,0 |

| 3.7 | 39,0 | 70,0 | 9.1 | 81,0 | 125,0 | 15.3 | 120,0 | 178,0 |

| 3,8 | 43,0 | 75,0 | 9.2 | 81,0 | 125,0 | 15,5 | 120,0 | 178,0 |

| 3.9 | 43,0 | 75,0 | 9.3 | 81,0 | 125,0 | 15,8 | 120,0 | 178,0 |

| 4.0 | 43,0 | 75,0 | 9.4 | 81,0 | 125,0 | 16.0 | 120,0 | 178,0 |

| 4.1 | 43,0 | 75,0 | 9,5 | 81,0 | 125,0 | 16.3 | 125,0 | 184,0 |

| 4.2 | 43,0 | 75,0 | 9.6 | 87,0 | 133,0 | 16,5 | 125,0 | 184,0 |

| 4.3 | 47,0 | 80,0 | 9,7 | 87,0 | 133,0 | 16,8 | 125,0 | 184,0 |

| 4.4 | 47,0 | 80,0 | 9,8 | 87,0 | 133,0 | 17.0 | 125,0 | 184,0 |

| 4,5 | 47,0 | 80,0 | 9,9 | 87,0 | 133,0 | 17.3 | 130,0 | 191,0 |

| 4.6 | 47,0 | 80,0 | 10.0 | 87,0 | 133,0 | 17,5 | 130,0 | 191,0 |

| 4.7 | 47,0 | 80,0 | 10.1 | 87,0 | 133,0 | 17,8 | 130,0 | 191,0 |

| 4.8 | 52,0 | 86,0 | 10.2 | 87,0 | 133,0 | 18,0 | 130,0 | 191,0 |

| 4.9 | 52,0 | 86,0 | 10.3 | 87,0 | 133,0 | 18,5 | 135,0 | 198,0 |

| 5.0 | 52,0 | 86,0 | 10.4 | 87,0 | 133,0 | 18,8 | 135,0 | 198,0 |

| 5.1 | 52,0 | 86,0 | 10,5 | 87,0 | 133,0 | 19.0 | 135,0 | 198,0 |

| 5.2 | 52,0 | 86,0 | 10.6 | 87,0 | 133,0 | 19.3 | 140,0 | 205,0 |

| 5.3 | 52,0 | 86,0 | 10.7 | 94,0 | 142,0 | 19,5 | 140,0 | 205,0 |

| 5.4 | 57,0 | 93,0 | 10.8 | 94,0 | 142,0 | 19,8 | 140,0 | 205,0 |

| 5,5 | 57,0 | 93,0 | 10.9 | 94,0 | 142,0 | 20,0 | 140,0 | 205,0 |